Instructions for Side by Side Printing

- Print the notecards

- Fold each page in half along the solid vertical line

- Cut out the notecards by cutting along each horizontal dotted line

- Optional: Glue, tape or staple the ends of each notecard together

Sampling

front 1 Sampling | back 1 obtaining objective, reliable information on a population |

front 2 Sample collection | back 2 a mechanical function and depends on: |

front 3 Sampling pattern | back 3 determined by the nature and geometry of mineralization

(i.e. |

front 4 Sample spacing | back 4 determined by the coefficient of variability (ratio of |

front 5 sample collection | back 5 the taking of representative |

front 6 sample preparation | back 6 processing of the samples |

front 7 Sample testing | back 7 sample analysis |

front 8 Grab Sampling | back 8 Quick approximation |

front 9 Percussion Drilling | back 9 churn drill |

front 10 Auger Drilling (Rotary) | back 10 low cost, speed and mobility |

front 11 Hand-operated augers | back 11 3 m with 10-15cm hole diameter |

front 12 Mechanically driven augers | back 12 up to >30 m or more depending |

front 13 Percussive Cum Rotary | back 13 Jackhammers, wagon drills |

front 14 Diamond Drilling (Rotary) | back 14 extensively used for mineral exploration, dam sites +

other |

front 15 drill rods | back 15 usually 10 feet (3.05 m) long through which water is |

front 16 Diamond core bit | back 16 a cylindrical |

front 17 Drilling mud | back 17 – (bentonite, barite) |

front 18 Core barrel | back 18 attached between the lower end of the drill rods |

front 19 Single tube | back 19 best core recovery condition or non-coring bits in |

front 20 Double tube | back 20 average core recovery, where the inner and outer |

front 21 “Triple tube | back 21 complex core barrels and expensive type used in |

front 22 Wire Line Drilling | back 22 saves considerable time and energy. |

front 23 Continuous Core Drilling | back 23 refers to circulating air down to the bit head outside the drill rods

and returning it up through inside the bit, |

front 24 RC Drillingv | back 24 - commonly used for open pit excavation of iron ore,

bauxite, |

front 25 core samples | back 25 from diamond drills or from the casing drills |

front 26 dry cuttings | back 26 from air-flushed diamond, rotary, auger or |

front 27 wet cuttings | back 27 or sludge from churn drills, diamond |

front 28 Soil Sampling/Talus Debris | back 28 Usually in scanty outcrops |

front 29 float samples | back 29 - for analyzing whether it would be useful in |

front 30 Pitting/Pit Sampling | back 30 Commonly during initial stage of surface

geochemical |

front 31 Trenching/Trench Sampling | back 31 10m and 3-5m deep |

front 32 tack/Dump Sampling | back 32 center, then 4 more from |

front 33  Muck Sampling | back 33 few handheld spade or mechanized shovels full of |

front 34  Alluvial Placer | back 34 Usually less-consolidated materials |

front 35 Channel Sampling | back 35 For uniformly distributed mineralization (veins,

stringers, |

front 36 Chip Sampling | back 36 For hard, dense irregularly distributed/disseminated mineralization |

front 37 Car & Sampling | back 37 Handful of the broken ore |

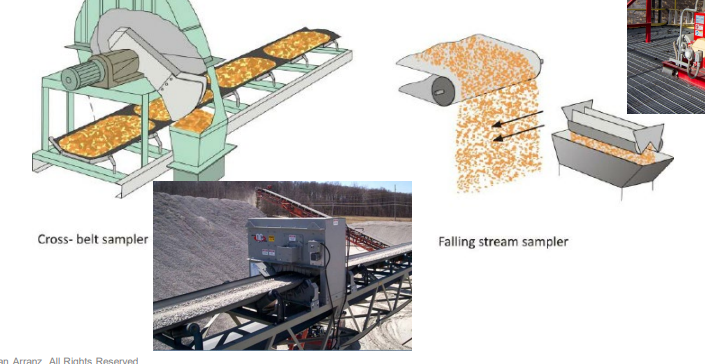

front 38  | back 38 Cross-Belt & Falling stream Sampling |

front 39 Bulk Sampling | back 39 normally of large volume (100 -1000 |

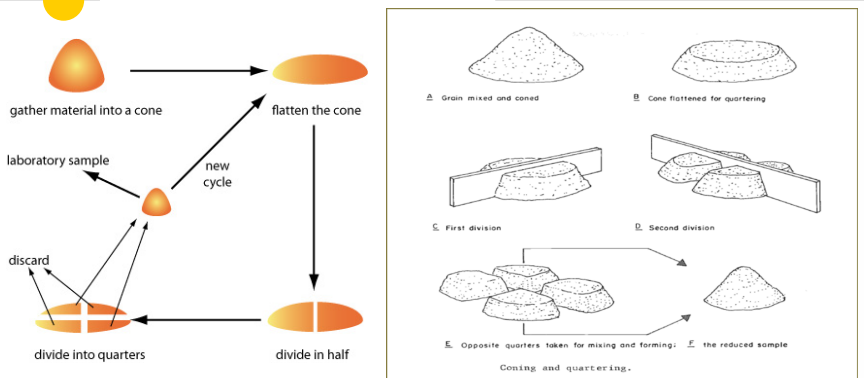

front 40  | back 40 Coning & Quartering |

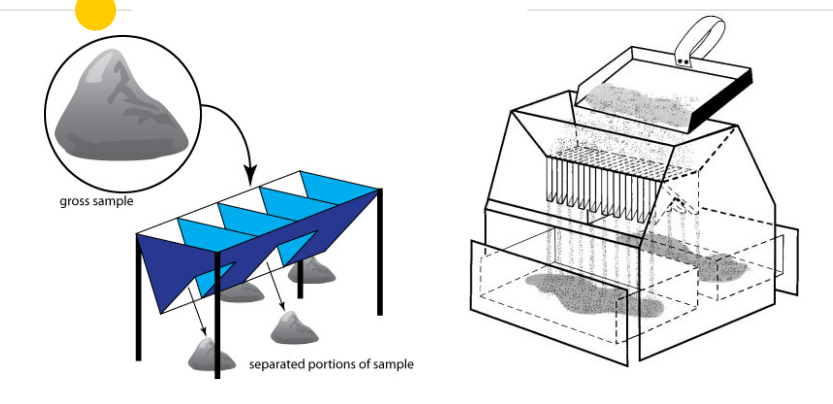

front 41  | back 41 Riffle Splitter |

front 42 ) Surface Exploration | back 42 - Pitting, Trenching, Stack and Placer sampling |

front 43 Surface and Underground | back 43 Diamond drill core, RC drill cuttings, Sludge, Channel and Chip sampling |

front 44 Quick Estimation of ROM (run-of-mine) grade | back 44 Grab, Muck, Car, Bulk sampling |

front 45 Thick (uniform) | back 45 Chip or Grab Sampling |

front 46 Medium (uniform) | back 46 Chip + Channel Sampling |

front 47 Too thin (in layers | back 47 Chip sampling |

front 48 Very Large | back 48 Large number of chip samples |

front 49 Gold, rare metals | back 49 Bulk Sampling |

front 50 Banded | back 50 Channel Sampling |