Sampling

obtaining objective, reliable information on a population

Sample collection

a mechanical function and depends on:

• sampling method,

•

site accessibility,

• geology,

• objectives of the project,

and

• requirements for statistical analysis.

Sampling pattern

determined by the nature and geometry of mineralization

(i.e.

size, shape, orientation, and distribution)

Sample spacing

determined by the coefficient of variability (ratio of

std. dev

to the mean) or in other words, the degree

of

homogeneity/heterogeneity of mineralization

sample collection

the taking of representative

fractions

sample preparation

processing of the samples

collected through reduction in size

and quantity

Sample testing

sample analysis

Grab Sampling

Quick approximation

- Randomly picked

Percussion Drilling

churn drill

suitable for soft and medium formation

-

relatively short holes (10-50 m)

Auger Drilling (Rotary)

low cost, speed and mobility

soft and loose

ground

inaccurate due to wall collapse & contamination

Hand-operated augers

3 m with 10-15cm hole diameter

Mechanically driven augers

up to >30 m or more depending

on subsoil

Percussive Cum Rotary

Jackhammers, wagon drills

air-driven drills with depth of

drilling limited to 6 m

for development of tunnels, advance

mining faces and

breaking big boulders in road and other

construction areas.

Diamond Drilling (Rotary)

extensively used for mineral exploration, dam sites +

other

foundation test works, mine development face, drainage

of

mine workings, mine vent., oil structure investigations &

oilgas wells

drill rods

usually 10 feet (3.05 m) long through which water is

pumped to

cool the bit + flush the rock cuttings

Diamond core bit

a cylindrical

hollow tube made of special alloys with a crown at

one end

Drilling mud

– (bentonite, barite)

prevents damage of drilling

tools,

serves as lubricant

Core barrel

attached between the lower end of the drill rods

and the reamer

shell. It holds the core inside while drilling and

brought to the surface.

Single tube

best core recovery condition or non-coring bits in

blast hole drilling

Double tube

average core recovery, where the inner and outer

tubes are

connected and rotate simultaneously

“Triple tube

complex core barrels and expensive type used in

broken, friable

and sheared formations

Wire Line Drilling

saves considerable time and energy.

withdrawing the core and inner tube assembly (core barrel) from

the hole without pulling out the hollow drill rods by a separate

hoisting unit fixed at a different pulley.

Continuous Core Drilling

refers to circulating air down to the bit head outside the drill rods

and returning it up through inside the bit,

core barrel and drill rods.

RC Drillingv

- commonly used for open pit excavation of iron ore,

bauxite,

limestone, rock phosphate, and coal seams.

- 10-15

cm large diameter vertical blast holes at high speed and

low cost

core samples

from diamond drills or from the casing drills

dry cuttings

from air-flushed diamond, rotary, auger or

percussion drilling, and

wet cuttings

or sludge from churn drills, diamond

drill, or wet rotary or

percussion drilling

Soil Sampling/Talus Debris

Usually in scanty outcrops

- Soil samples are collected on a

relatively closely spaced

rectangular/square grid pattern at

specified intervals

float samples

- for analyzing whether it would be useful in

the detection of

concealed mineralization with a thin cover

Pitting/Pit Sampling

Commonly during initial stage of surface

geochemical

exploration

- Excavating 1x1 m2 pits in

rectangular or square grid

patterns covering the entire target

area w/ varying depths

depending on extent of weathering and

nature of rocks

Trenching/Trench Sampling

10m and 3-5m deep

Trenches are often cut across

the orebody after

the

probable configuration of

mineralization is

outlined

either by pitting or by

rock/soil sampling

tack/Dump Sampling

center, then 4 more from

halfway to the corners

collection of representative

broken material generated

by

pitting, trenching, mine

production etc.

Muck Sampling

few handheld spade or mechanized shovels full of

mineralized

fragments and fines collected from the mine

face or stope draw points

Alluvial Placer

Usually less-consolidated materials

(weathered) but

stratified

- Scooping by hand spade or by auger

drills

Channel Sampling

For uniformly distributed mineralization (veins,

stringers,

disseminations)

- cutting of channels across

mineralized body in fresh surface

exposures/underground mine

workings ( face, walls and

roof)

Chip Sampling

For hard, dense irregularly distributed/disseminated mineralization

- chipping off same-sized fragments of about 1x1 to 2x2 cm size

covering the entire surface exposure, underground

mine face, wall

and roof in a regular grid interval (25x25 cm)

Car & Sampling

Handful of the broken ore

material picked up randomly

every

5th/10th… moving car

transported by mine-car

from

underground operations,

dumpers/trucks

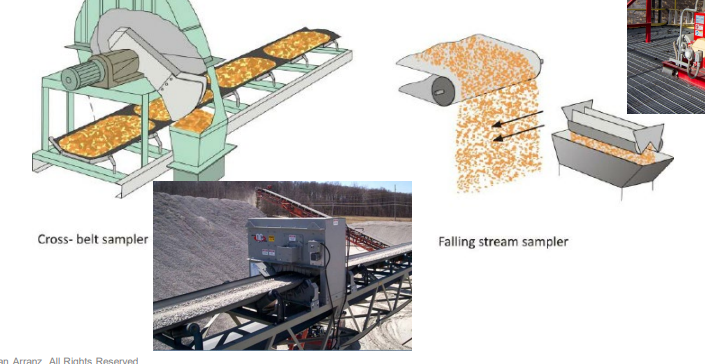

Cross-Belt & Falling stream Sampling

Bulk Sampling

normally of large volume (100 -1000

tonnes) representing all the

distinctive

characteristics of the orebody

- From different parts of stockpile of trial

pit (surface),

trial crosscuts

(underground) and ROM of regular

production

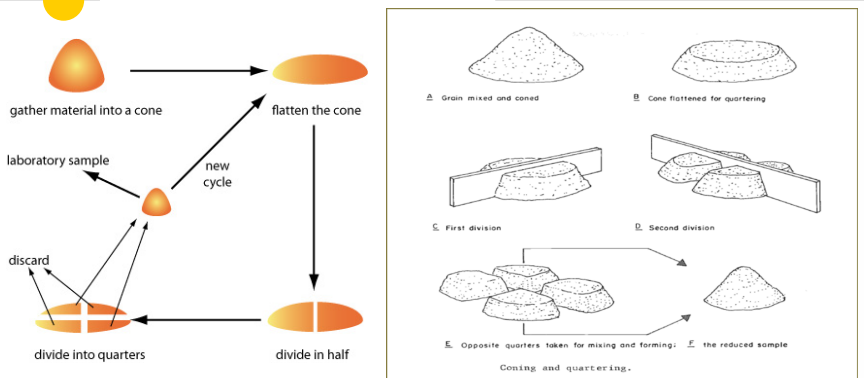

Coning & Quartering

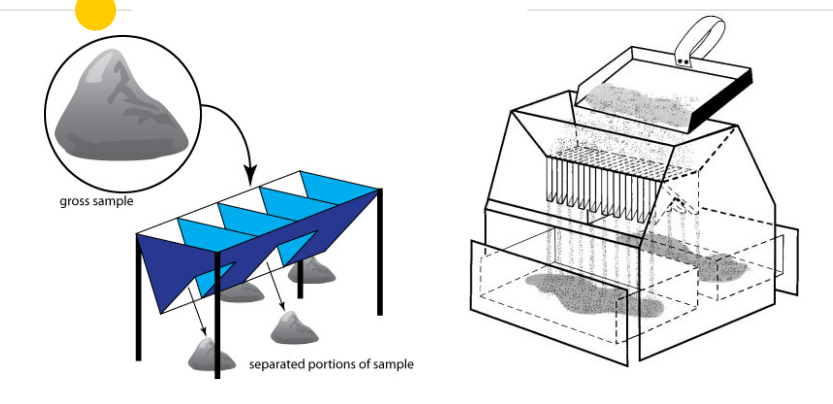

Riffle Splitter

) Surface Exploration

- Pitting, Trenching, Stack and Placer sampling

Surface and Underground

Diamond drill core, RC drill cuttings, Sludge, Channel and Chip sampling

Quick Estimation of ROM (run-of-mine) grade

Grab, Muck, Car, Bulk sampling

Thick (uniform)

Chip or Grab Sampling

Medium (uniform)

Chip + Channel Sampling

Too thin (in layers

Chip sampling

Very Large

Large number of chip samples

Gold, rare metals

Bulk Sampling

Banded

Channel Sampling