COMMINUTION

Size reduction by particle breakage

▪ liberation

• Create

particles in certain size and

shape

• Increase surface area

available for next

process

Comminution usually accounts for more than ____ total power

40 % to 50%

Only about ____ of the energy input is used to comminute

3% – 5 %

Problems associated with comminution:

➢ It is mechanically a wasteful process.

➢ Most of the energy

input is lost to a lot of factors.

▪ Absorbed by the

equipment

▪ Water resistance in pulp

▪ Deformation (not

breakage) of plastic particles

➢ Heat is unavoidably produced.

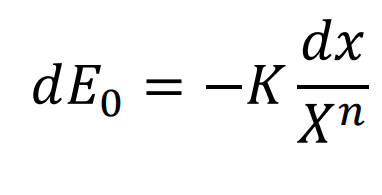

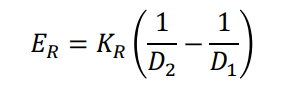

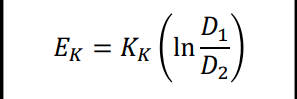

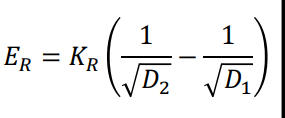

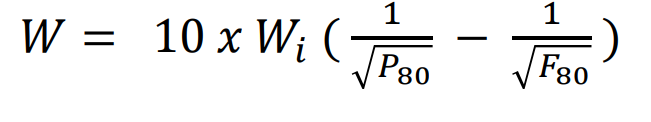

An empirical relationship between energy consumed during size reduction and particle size.

Rittinger’s Law

energy of breakage ∝ amount

of new surfaces produced

Kick’s Law

energy required ∝ reduction in volume of the particles concerned

Bond’s Law

energy required ∝ new crack

tip length produced in particle

breakage

Work Index

Energy required to reduce one ton of ore from a very large size to 100µm

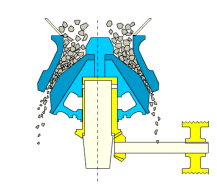

Jaw Crusher

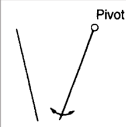

1) Blake

2) Dodge Type

BlakeS

Movable jaw is pivoted at the top

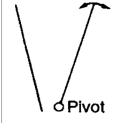

Dodge Type

Movable jaw is fixed at the bottom

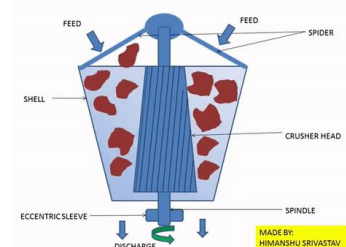

Relative motion of the crushing faces is

due to gyration motion

of an

eccentrically mounted cone

gyratory crusher

Comminution by impact; sharp blows on free-falling rock

IMPACTORS

Modified gyratory crusher that yields smaller product

CONE CRUSHERS

Consists of two horizontal cylinders

revolving towards each other

ROLL CRUSHERS

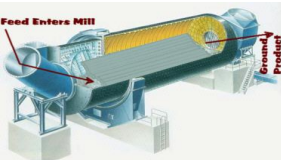

GRINDING

Last stage in comminution

process

Grinding Size Reduction

impact + abrasion

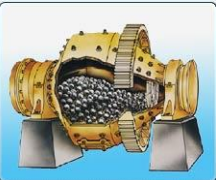

What is used when grinding

medium is present

balls or rods

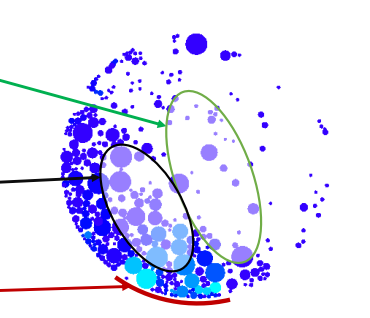

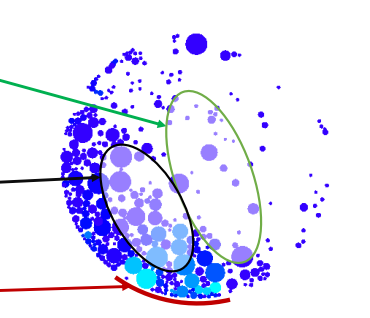

Green

• Parabolic path taken by charge as

projected by lifting of

the mill

• Coarse grinding by impact

Cataracting

Black

• Rolling motion of the charge down to

the toe

• Leads

to finer grinding by abrasion

Cascading

Red

Charge is carried around in a fixed

position

Centrifuging

Uses cast iron rods

as grinding medium

Rod Mill

Uses forged steel

balls as grinding

medium

Ball Mill

The action of the ore grinding upon itself with small amount of ball charge

Semi-autogenous Mill

SIZING

Selection of materials based on their size

SCREENING (Industrial Screening)

Use of screening equipment (screens)

• Extensively used for size separations from 300 mm down to

roughly 40 µm, efficiency decreases rapidly with fineness

Screen equipment are classified as

stationary and moving

SCREENING objectives

To optimize the feed of the comminution stage by preventing

the

materials which are already smaller, not to enter this

stage

• To ensure that the desired product is according to the

size

application

• To ensure that the feed to succeeding

process does not exceed

size limitation of receiving area

Sizing/Classifying

To separate particles by size

Scalping

To remove coarsest size fractions in the feed material

Grading

To prepare a number of products within specified size ranges

Media recovery

For washing magnetic media from ore in dense medium circuits; or to retain grinding media inside grinding mills

Dewatering

To drain free moisture from a wet sand slurry

De-sliming/De-dusting

To remove fine material, generally below 0.5 mm, from a wet or dry feed

Trash removal

Usually to remove coarse wood fibers or tramp material from a slurry stream

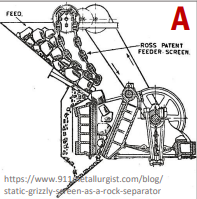

Static Grizzlies

• 35 – 50° deck angle

• Uses heavy parallel bars

• Used

with coarse crushing

(scalping operations)

Sieve Bends

• >50μm, 180m3/hr

• Curved screen w/ horizontal

wedge

bars

• Slurry enters tangentially to

the bend

• Peeling

action of the slurry

bed

stationary screens

1. Static Grizzlies

2. Sieve Bends

moving screens

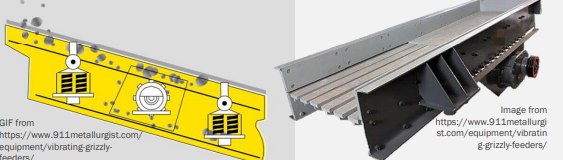

Grizzly Screens

Trommels

Grizzly Screens

• Usually screens very coarse

material

• Characterized by

parallel steel

bars on rails set at a fixed

distance apart

and installed in

line with the flow of ore

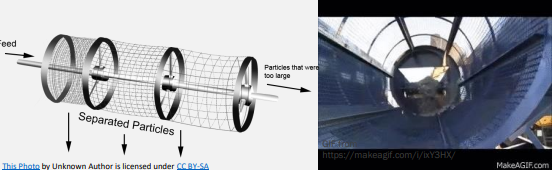

Trommels

• Comprised of a cylindrical screen

• Can be made to deliver

sized

products by using a series from

finest to coarsest or

using

concentric trommels with the

coarsest mesh being innermost

CLASSIFICATION

LESS Than 1mm

Method of separating mixtures of minerals into 2 or more

products based on the velocity of the particles as the grains

fall

through a fluid medium (liquid or gas)

Wet classification

usually uses water, generally applied to

mineral particles

considered too fine to be sorted efficiently by screening

CLASSIFIERS

• used for particles 1mm or less

CLASSIFIERS categorized by force field applied to unit

either gravitational or centrifugal

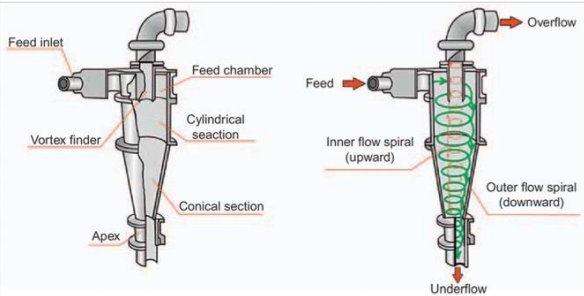

Hydrocyclone

Utilizes centrifugal force to accelerate settling rate of particless

gravitational classifiers

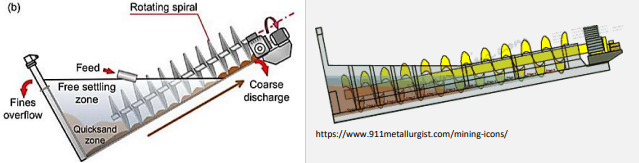

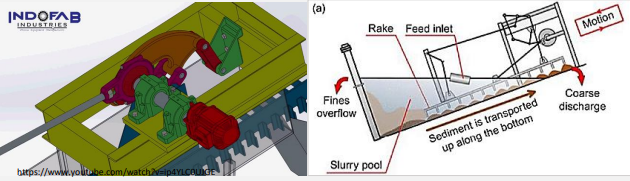

Spiral Classifier

Rake Classifier

Spiral Classifier

A continuously revolving spiral moves the sands up the slope

Rake Classifier

Uses rakes actuated by an eccentric motion, which causes them to dip into the settled material and move up the incline for a short distance

GRAVITY CONCENTRATION

• Most simple and economical of all concentration methods

•

Particles are separated by their differences in density

• Greater

density difference = easier separation

Dense Media

Separation

Particles are placed in a

liquid of known density.

Denser

particles sink

while lighter particles float

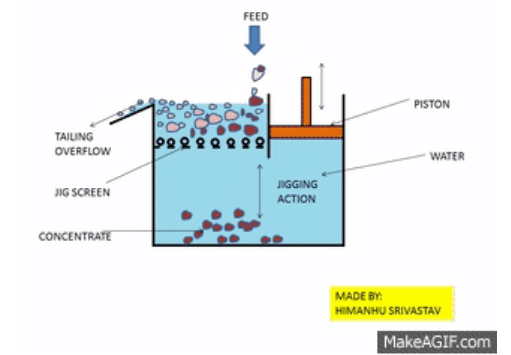

Vertical Current

Separation

Stratification of mineral

layers based on their

densities

on a particle

bed, fluidized by a stream

of water

Jigging

Shaking Table

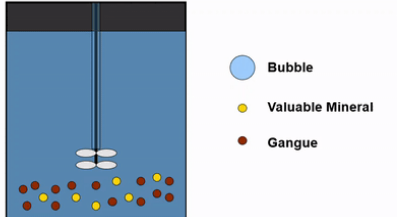

Separation via altering surface-chemical properties of minerals

bubbles

FROTH FLOTATION

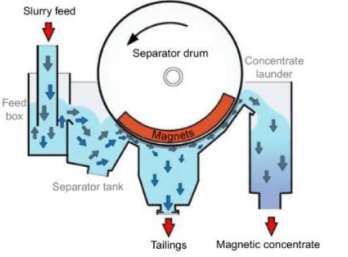

• Uses the difference in magnetic

properties between minerals

Magnetic Separation

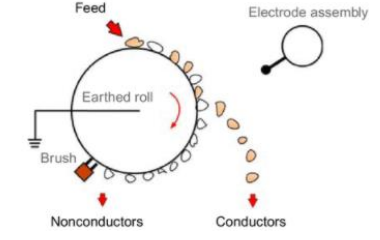

Uses the difference in electrical

conductivities between minerals

High Tension Separation

DEWATERING

Solid – Liquid Separation

• Produces a relatively

dry

concentrate (less shipping

volume)

• For certain

processes that

requires low H2O content

Dewatering (combination of the

three)

Sedimentation

Filtration

Thermal Drying

Sedimentation

Increases concentration

of suspensions by

settling solids

Filtration

Uses a porous medium that blocks solids (filter cake) and allows liquids (filtrate) to pass through.

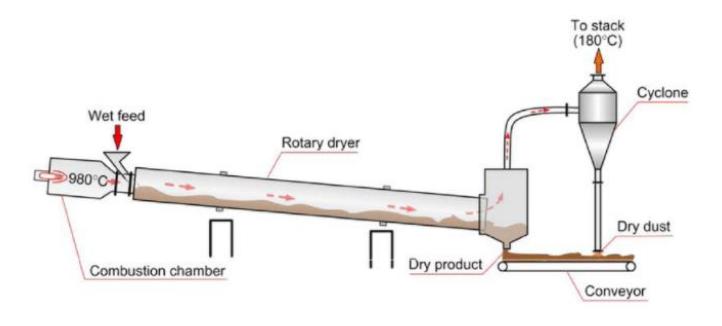

Thermal Drying

Final operation in a mineral processing

plant. Moisture content

is lowered to ~5 wt%

Sedimentation

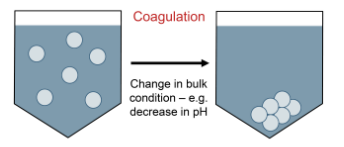

Coagulation

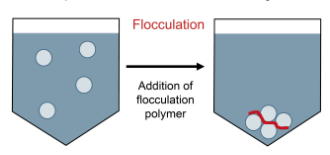

Flocculation

Coagulation

Neutralizes charged particles so that they

will settle and not

continuously repel each other

Flocculation

Uses long-chain polymers to bridge particles until they areheavy enough to settle

THERMAL DRYING | rotary dryer

ORE HANDLING

Costs account for 30 – 60% of total delivered price of raw materials

• Covers the processes of transportation, storage, feeding,

washing, and sampling of the ore en route to, or during its

various

stages of treatment in the mill

ORE TRANSPORTATION

Minimum upward and horizontal movement

• Maximum practicable

pulp density

ORE TRANSPORTATION (Basic Philosophy)

• The use of gravity should be maximized.

• There should be

continuous movement.

• Shortest possible distances in between

processing units should be

utilized.

ORE TRANSPORTATION | dry ore

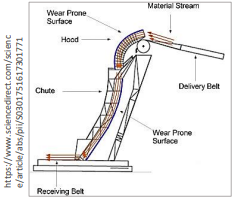

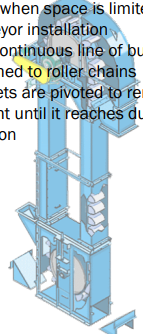

Chutes

(Standard Rubber) Belt Conveyor

Gravity Bucket Elevators

Chutes

(Standard Rubber) Belt Conveyor

Gravity Bucket Elevators

ORE STORAGE

Necessity arises from successive processing units performing

at

different rates

▪ Intermittent vs. continuous, for

repairs, and for successive batch and

continuous processes

ORE STORAGE Depends on

▪ The equipment in the mill / method of operation

▪ Frequency of

maintenance work required

ORE STORAGE Accomplished by having

stockpiles, and using bins or tanks

ORE STORAGE

Stockpiles

Ore Bins

Slurry Tanks / Conditioning Tanks

Can be reclaimed by front-end

loaders or bucket-wheel

reclaimers

Stockpiles

• Used as intermediate between

crushing and grinding

circuits

• They allow the steady discharge of

ore w/o

segregation or choking

• Sloping-bottom bins for

easily

oxidized ore

Ore Bins

• For storing suspensions of fine

solids with provisions for

agitation

for suspension of solids or

prerequisite chemical reactions

Slurry Tanks/Conditioning Tanks

ORE FEEDING

Desired for delivery of uniform stream of ore

• Unnecessary for cases when succeeding operations have

same

rates of flow

• Used for smooth control of bin discharge

• Consist of curtain of heavy loops of chain which when moves,

the ore begins to

slide

A. Chain Feeders

• Essentially a conveyor with abrasion-resistant steel pans attached

in series

• Most widely used feeder for coarse materials

B. Apron Feeders

• Remove fines from coarse

particles before crushing

•

“Scalping” the ore to prevent

consolidation of fines

C. Vibrating Grizzlies

• Long elliptical bars in alternate

vertical and horizontal

positions

all rotating in one direction

• Rocking action

sifts the ore; the

fines fall through to a conveyor,

the

coarsest tumbles across to

crushe

D. Elliptical Bar Feeder

Hand Sorting

used when in abundance of cheap manual labor, or additional equipment installation is not economically justified

Magnetic Separators

situated above conveyors to pick up large pieces of tramp iron and steel; used w/ metal detectors

Vibrating Scalping Screens

removal of wood from pulp (wood causes choking)

Washing

▪ removal of slimes (very fine particles)

• Uses high-pressure

water jets over vibrating screens

Measures of Efficiency

DEGREE OF LIBERATION

MESH-OF-GRIND

PARTICLE SIZE ANALYSIS

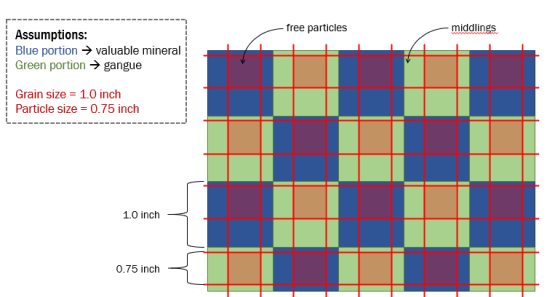

DEGREE OF LIBERATION

The percentage of a mineral or phase occurring as free particles in relation to the total of the minerals in the ore

MESH-OF-GRIND

The size up to which the ore is ground to ensure

sufficient

liberation of wanted mineral

• Normally taken as

80% passing product

• Balance between liberation and economics

(longer grinding duration =

higher costs)

PARTICLE SIZE ANALYSIS

Control of quality of grinding

• Measure of degree of

liberation

• Determining the optimum feed size

•

Establishing the grinding limit to reduce losses